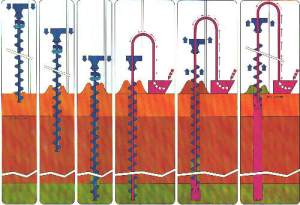

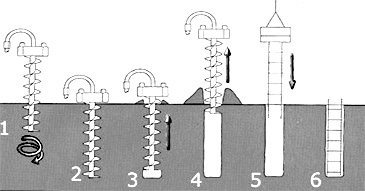

Since their introduction some fifty years ago in North America, continuous flight auger (CFA) piles, also known as augercast piles, have become increasingly popular, as they can be considerably cheaper than alternative pile types. With proper planning and design, efficient equipment and experienced personnel, high production rates can be achieved.

The CFA equipment comprisesa base machine with a fixed,swinging or hanging lead, an auger drive unit (hydraulic or mechanic) and a continuous flight auger equipped with auger cutting heads. For more info about the installation process, placing of reinforcement, etc, please, clic here:

– Installation process

– Casting of pile base and shaft

– Placing of reinforcement

– Advantages

– Limitations

– Soil decompression during augering

Source: Pile info